Revolutionizing the Factory Floor: The Rise of AI-Powered ERP Systems

The Dawn of Intelligent Manufacturing

For decades, enterprise resource planning (ERP) systems have been the backbone of business operations, streamlining processes from finance to human resources. However, the manufacturing sector, particularly the millions of factories globally that form the bedrock of our economy, faces unique challenges that traditional ERP systems often struggle to fully address. Enter a new generation of ERP: systems powered by artificial intelligence (AI), specifically designed to transform the factory floor.

Imagine a system where repetitive workflows aren’t just managed, but intelligently automated. Where machines learn, adapt, and even predict needs, freeing up human ingenuity for more complex, strategic tasks. This isn’t a distant future; it’s the present reality being built by innovative companies.

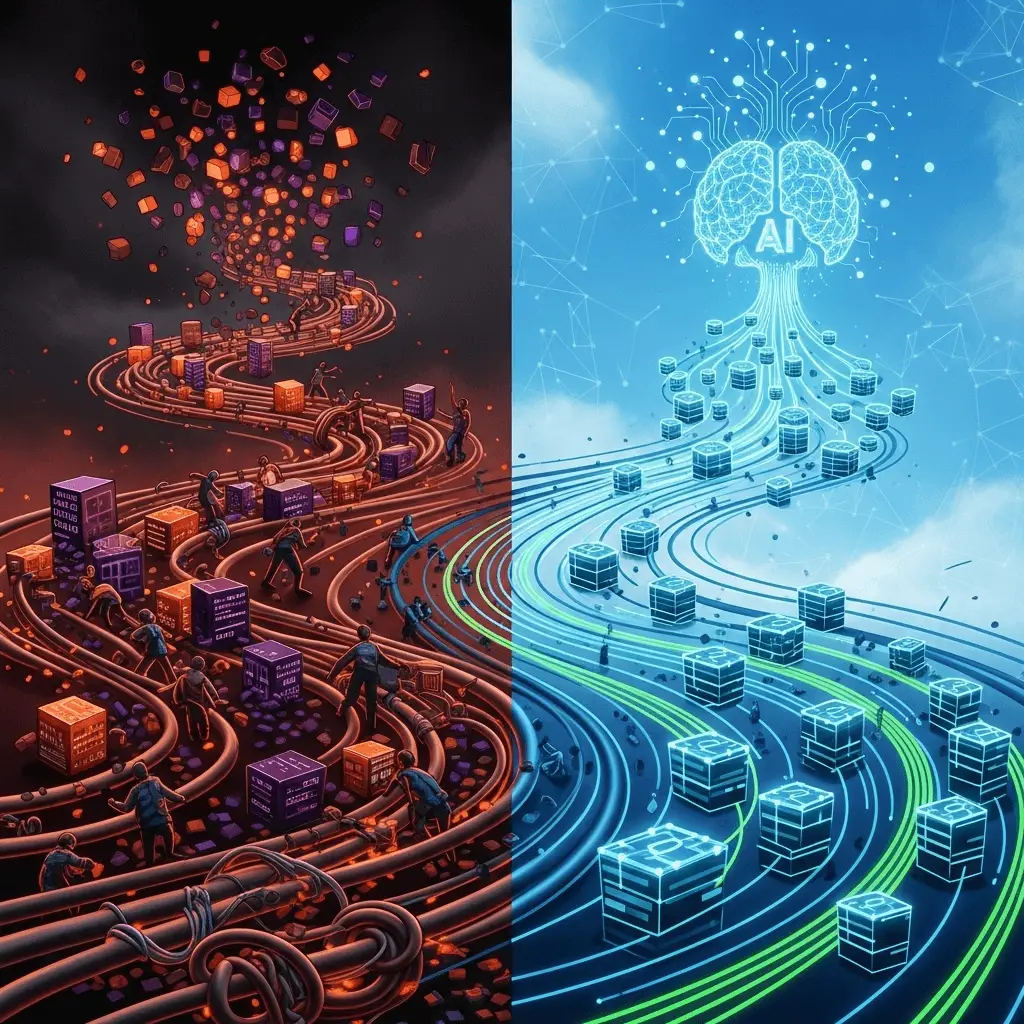

Bridging the Gap: Why Traditional Factories Need AI-Powered ERP

Many of the world’s approximately four million factories still operate with a significant reliance on manual processes, disparate legacy systems, or older ERP solutions not designed for the complexities of modern, data-rich manufacturing. This often leads to:

- Inefficiency and Bottlenecks: Manual data entry, cumbersome approval processes, and lack of real-time insights can slow down production.

- High Operational Costs: Inaccurate inventory, unplanned downtime, and suboptimal resource allocation directly impact the bottom line.

- Limited Scalability: Growing production or adapting to market changes becomes challenging without flexible, integrated systems.

- Data Silos: Information remains isolated within different departments, preventing a holistic view of operations.

These challenges highlight a critical need for solutions that can not only organize data but actively use it to drive smarter operations.

Introducing AI-Powered ERP: A Game Changer

The core of next-generation ERP systems for factories lies in their ability to leverage AI agents to automate workflows. Unlike traditional automation, which follows predefined rules, AI agents can:

- Learn from Data: Analyzing vast amounts of operational data to identify patterns, predict outcomes, and optimize processes.

- Adapt and Evolve: Continuously improving their performance based on new information and changing conditions.

- Make Intelligent Decisions: Automating tasks that traditionally required human judgment, such as dynamic scheduling or anomaly detection.

This paradigm shift turns the ERP system from a passive record-keeper into an active, intelligent partner in manufacturing.

Automated Workflow Management

AI agents can revolutionize production scheduling, demand forecasting, and supply chain management. By analyzing historical data, market trends, and real-time factory conditions, they can optimize production lines, minimize waste, and ensure timely delivery, drastically reducing human effort in planning and coordination.

Predictive Maintenance

Instead of reactive repairs, AI can predict equipment failures before they occur. Sensors collect data on machine performance, and AI algorithms identify subtle anomalies, scheduling maintenance proactively. This minimizes downtime, extends equipment life, and saves significant costs.

Quality Control & Anomaly Detection

AI-powered vision systems and data analytics can monitor production lines in real-time, instantly identifying defects or deviations from quality standards. This ensures consistent product quality and reduces scrap rates far more efficiently than manual inspections.

Intelligent Inventory Management

AI agents can optimize inventory levels by accurately predicting material needs, managing reorder points, and even negotiating with suppliers automatically. This reduces holding costs, prevents stockouts, and enhances overall supply chain resilience.

The Tangible Benefits for Manufacturers

Implementing an AI-powered ERP system offers a host of advantages:

- Increased Efficiency: Streamlined operations, reduced manual labor, and faster decision-making.

- Reduced Operational Costs: Savings from optimized resources, less waste, predictive maintenance, and improved quality.

- Enhanced Accuracy: Minimized human error in data entry and complex calculations.

- Improved Agility: Greater flexibility to adapt to market changes, new product lines, and supply chain disruptions.

- Data-Driven Insights: Real-time analytics and predictive capabilities empower better strategic planning.

- Competitive Advantage: Positioning factories at the forefront of Industry 4.0 innovation.

The Future of Factory Operations is Here

Companies like ‘Tiny’ represent the vanguard of this transformation, building next-generation ERP systems specifically tailored for the manufacturing sector. By focusing on AI agents that automate repetitive workflows, they’re not just offering an upgrade; they’re providing a complete reimagining of how factories operate.

For the four million factories striving for efficiency, resilience, and growth in a competitive global landscape, AI-powered ERP isn’t just an option—it’s becoming an essential component of their future success.